Trustworthy Industrial Scales Constructed for Heavy-Duty Applications

Trustworthy Industrial Scales Constructed for Heavy-Duty Applications

Blog Article

Enhance Your Company Operations With Reliable Industrial Scales

In today's competitive landscape, the accuracy of commercial ranges plays a crucial role in improving total company operations. As companies seek to optimize efficiency, understanding the different types of scales and their technical developments ends up being important.

Significance of Accurate Weighing

Exact considering is critical in numerous industrial applications, as even small inconsistencies can lead to significant operational inefficiencies and monetary losses. Industries such as production, logistics, and food handling depend upon exact dimensions to guarantee item quality, governing conformity, and ideal resource management. Unreliable weights can lead to overflow, wastage of resources, or poor supply, affecting profitability and customer complete satisfaction.

In addition, exact evaluating is essential for security and ecological conformity. In the chemical market, inaccurate measurements can lead to improper mixtures, resulting in lawful implications or unsafe circumstances. In the food market, accurate considering is important for sticking to dietary labeling needs, making certain that consumers receive exact details concerning the items they purchase.

The integration of dependable industrial ranges not only improves functional performance however additionally sustains data-driven decision-making. Firms that prioritize specific evaluating can optimize stock administration, streamline supply chains, and decrease expenses associated with returns and rework. Investing in top quality industrial evaluating solutions is essential for organizations intending to preserve an affordable side in today's vibrant marketplace. Accurate weighing ultimately functions as a foundation for functional quality and lasting development.

Kinds Of Industrial Scales

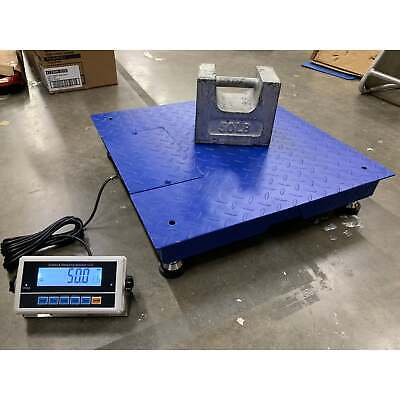

Industrial ranges come in numerous kinds, each developed to fulfill details weighing requirements throughout different industries. Among the most typical kinds are system scales, which give a huge weighing surface suitable for hefty things, making them suitable for warehouses and manufacturing facilities. These scales often include digital display screens for very easy analysis.

An additional kind is bench scales, which are usually smaller and mobile, perfect for use in labs or retail atmospheres. They allow for quick measurement of smaller sized things while keeping precision. For applications needing the considering of fluids, storage tank scales are particularly designed to measure the weight of storage containers, making sure accurate stock monitoring.

Crane scales are likewise notable; they are suspended from a structure to consider heavy materials in commercial settings. Each type of commercial scale offers an one-of-a-kind objective, boosting operational performance across varied markets.

Advantages of Modern Modern Technology

Moreover, modern-day industrial scales often come equipped with connectivity functions that enable seamless integration with other systems, such as supply administration and production tracking. This interconnectivity fosters an extra cohesive workflow and lessens downtime, as services can check performance metrics and make data-driven decisions immediately.

Additionally, lots of modern scales use easy to use user interfaces and customizable setups, allowing operators to adjust their devices for particular operational needs. Enhanced durability and durability versus extreme ecological conditions further add to the long life and dependability of modern-day scales, ensuring they can stand up to company website the roughness of commercial usage.

Selecting the Right Tools

Different markets might require unique kinds of ranges, such as floor ranges for hefty loads, bench scales for smaller sized things, or portable scales for adaptability. Furthermore, thinking about the setting in which the scales will be utilized is essential. As an example, equipment used in severe environments may require to be sturdy and resistant to dirt, wetness, or severe temperature levels.

An additional vital variable is the technology used in the scales. Digital ranges usually use enhanced precision and convenience of use, while analog scales may suffice for less demanding applications. Additionally, it is essential to review the scalability of the equipment, ensuring that it can suit future growth or adjustments in manufacturing procedures.

Last but not least, companies should take into consideration the credibility and integrity of makers, as buying premium equipment can cause long-lasting expense financial savings and boosted operational efficiency.

Maintenance for Durability

Routine maintenance is vital for making sure the long life and ideal efficiency of industrial scales. A systematic strategy to upkeep not just extends the life of the devices however additionally ensures precise measurements essential for functional effectiveness.

Begin with regular evaluations to recognize wear and tear, making certain parts such as load cells and displays work correctly. Calibration checks need to be conducted routinely, preferably after substantial modifications in environmental conditions or complying with heavy use. Accurate calibration is crucial for conformity with sector over at this website criteria and for keeping the dependability of weight measurements.

Furthermore, it is advisable to develop a maintenance timetable that tapes each solution go to, calibration, and any repair work executed. This paperwork help in tracking tools performance and preparation for future maintenance requirements.

Last but not least, educating staff on appropriate usage and treatment techniques will lessen the possibility of driver error, better improving range integrity. By prioritizing routine maintenance, companies can make certain that their industrial ranges remain a dependable possession in their operations.

Verdict

In summary, the assimilation of trustworthy commercial ranges is necessary for boosting business operations throughout different fields. Precise considering not only lessens inconsistencies but additionally enhances inventory management and makes certain conformity with industry criteria. The selection of proper devices, paired with contemporary technological innovations, can significantly enhance performance and decrease functional costs. Regular maintenance and training more add to the durability and precision of these scales, cultivating data-driven decision-making and inevitably sustaining total service success.

Industrial scales come in different kinds, each designed to satisfy certain weighing needs across various sectors. Crane ranges are likewise significant; they are suspended from a framework to evaluate heavy materials in commercial setups.Various industries may call for unique types of ranges, such as floor scales for heavy tons, bench ranges for smaller sized things, or mobile scales for adaptability - Industrial Scales. Digital ranges typically supply boosted precision and simplicity of usage, while analog scales might be enough for less demanding applications.In recap, the combination of reliable industrial ranges is necessary for enhancing service operations throughout various industries

Report this page